Review our guide to the best online construction engineering programs to learn about your education options in a growing field.

Contents

What Is an Online Construction Engineering Program?

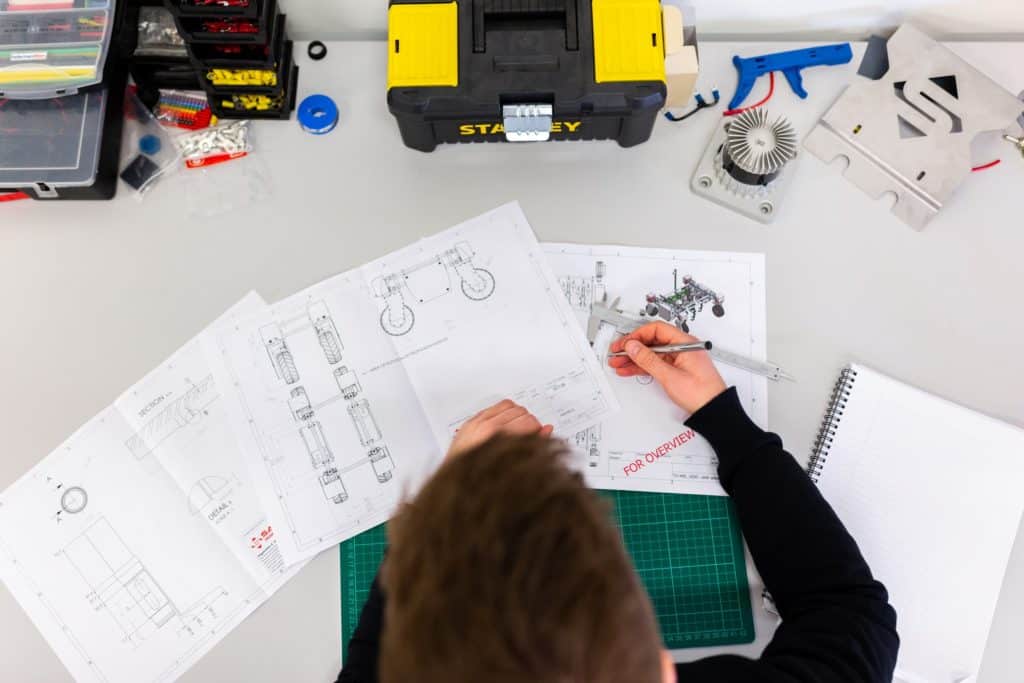

A program that prepares individuals to apply scientific, mathematical, and management principles to the planning, design, and building of facilities and structures. Includes instruction in civil engineering, structural principles, site analysis, computer-assisted design, geology, evaluation and testing, materials, contracting, project management, graphic communications, and applicable laws and regulations.

How Much Does an Online Construction Engineering Program Cost?

The cost of an online construction engineering program depends on what program you choose and what school you choose to go to. An online construction engineering program can cost as little as $11,000. However, they can also cost as much as $50,000 for tuition.

Average Salary for an Online Construction engineering Program

The median salary for a civil engineer is $88,750 per year. For a job like construction manager, the average median salary is $97,180 per year.

What Is the Job Outlook for Graduates of Online Construction engineering Programs

The employment outlook for students hoping to begin a career in construction engineering is very good for those graduates who are planning to work as a construction manager. Jobs are expected to grow by 8% by 2029. Civil engineers will have fewer job opportunities, since the field is only expected to grow by 2% by 2029, which is slower than the average field.

Courses in an Online Construction engineering Programs

Certificate programs and associate career training degrees in construction engineering lead to entry-level positions in the field. Students in online construction engineering programs will take courses in categories including engineering, sciences, math, and the humanities. More specialized courses may include digital graphics, methods and materials of construction, history of the built environment, mechanical and electrical systems, plumbing systems, structural design, construction safety, project management, surveying, and more.

FAQs on Online Construction engineering Programs

Summary Information

- The benefit of an online degree in construction engineering is that you can learn without a commute and structure your time.

- Accelerated online construction engineering programs will help you reach your career goals in 2 years or less.

- Many online construction engineering programs allow you to concentrate on a specific area in construction engineering, so you can start in the specific part of the field that most interests you.

- Technology is evolving and construction engineering is growing. Thus, the job outlook is good.

- Jobs in construction engineering range in salary, but many pay close to $100,000 per year on average.

- Professionals in online construction engineering help people make their dreams a reality, and they get to exercise creative muscles.

- The tuition price for an online construction engineering program differs based on the program you choose.

- Accelerated construction engineering programs are often more affordable.

- To complete an online construction engineering program, you’ll need your own computer and an internet connection.